Diamond blades are powerful tools. They cut through tough materials with ease.

But using them safely is crucial. Mistakes can lead to accidents or damage. In this comprehensive guide, you’ll learn the best practices for using diamond blades safely. Whether you’re a professional or a DIY enthusiast, understanding these safety tips is essential.

We’ll cover everything from selecting the right blade to proper handling techniques. You’ll also find advice on maintenance and storage to extend the life of your diamond blades. By following these guidelines, you can ensure a safer working environment and achieve better results in your cutting projects. Let’s dive into the details and make your cutting tasks efficient and safe.

Choosing The Right Diamond Blade

Choosing the right diamond blade is crucial for safe and efficient cutting. A diamond blade’s performance depends on its compatibility with the material and its specifications. This guide will help you understand the key aspects to consider.

Material Compatibility

Different diamond blades are designed for specific materials. Using the wrong blade can result in poor performance or damage. Here are some common materials and their compatible diamond blades:

- Concrete: Use a segmented diamond blade.

- Asphalt: Opt for a soft-bonded diamond blade.

- Marble: Choose a continuous rim diamond blade.

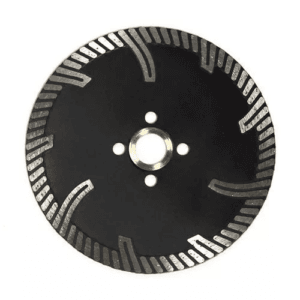

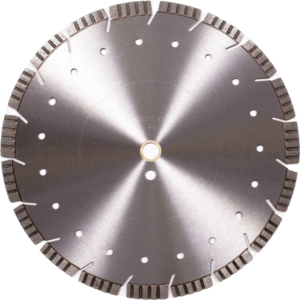

- Tile: A turbo rim diamond blade works best.

- Granite: Use a segmented or turbo rim diamond blade.

Ensure the blade matches the material for effective and safe cutting.

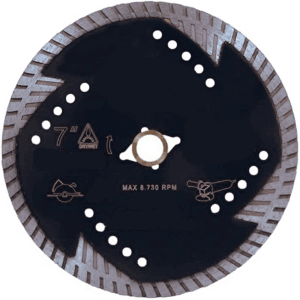

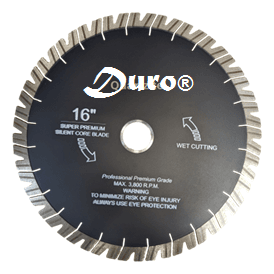

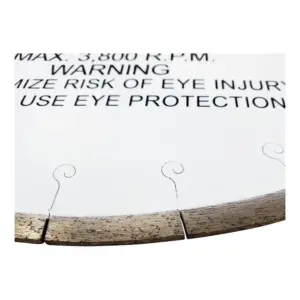

Blade Specifications

Diamond blades come with various specifications. Understanding these helps in making the right choice. Here are some key specifications to consider:

| Specification | Description |

|---|---|

| Blade Diameter | The size of the blade. Common sizes range from 4 to 14 inches. |

| Arbor Size | The diameter of the hole in the center of the blade. Ensure it matches your saw. |

| Segment Height | The height of the diamond segments. Higher segments provide a longer lifespan. |

| Bond Hardness | Indicates the hardness of the bond holding the diamonds. Choose based on the material. |

These specifications ensure the blade fits your tool and suits your cutting needs.

Credit: imsbolt.com

Pre-use Inspection

Before using a diamond blade, it’s important to perform a thorough pre-use inspection. This ensures the blade is safe and ready for use. Checking the blade prevents accidents and prolongs its lifespan. Follow these steps to inspect the blade properly.

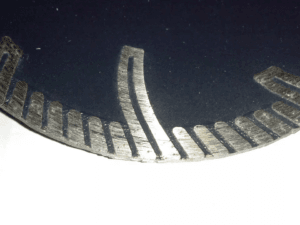

Checking For Damage

Inspect the diamond blade for any visible damage. Look for cracks, chips, or warping. Damaged blades can break during use. This can cause injury. Ensure the blade is free from any defects. If you see damage, do not use the blade.

Ensuring Proper Mounting

Make sure the blade is mounted correctly on the tool. Incorrect mounting can cause the blade to wobble. This can lead to uneven cuts and accidents. Check that the blade is secure and properly aligned. The blade should fit snugly without any play.

Ensure the mounting arbor matches the blade’s hole size. A mismatch can cause the blade to spin unevenly. This can result in dangerous situations. Always use the correct arbor size for your blade.

Personal Protective Equipment

Using diamond blades requires a strong focus on safety. Without proper protection, injuries can occur. This section discusses essential personal protective equipment (PPE) to keep you safe.

Safety Gear Essentials

Wearing the right safety gear is crucial. Here are some essentials:

- Safety Glasses: Protect your eyes from flying debris.

- Ear Protection: Use earplugs or earmuffs to protect your hearing.

- Dust Mask: Prevents inhalation of harmful dust particles.

- Gloves: Shield your hands from cuts and abrasions.

- Steel-toed Boots: Protect your feet from heavy objects.

Proper Attire

Wearing proper attire is just as important as safety gear. Here’s what you need:

- Long Sleeves: Cover your arms to prevent cuts and burns.

- Long Pants: Protects your legs from debris.

- Non-slip Shoes: Ensure a firm grip on the ground.

Combining safety gear with proper attire enhances your protection. Always prioritize safety first when using diamond blades.

Proper Cutting Techniques

Proper cutting techniques are essential for safely using diamond blades. Understanding these techniques ensures accurate cuts and prolongs the blade’s life. It also helps prevent accidents and injuries. This section covers straight cuts and curved cuts, providing step-by-step guidance for each.

Straight Cuts

For straight cuts, start by marking the cutting line on the material. Use a pencil or chalk for this. Secure the material firmly to prevent movement. Align the blade with the marked line before starting the saw. Begin cutting slowly, letting the blade do the work. Maintain a steady hand and follow the line carefully. Do not force the blade; this can cause it to overheat or break.

Curved Cuts

Curved cuts require a bit more skill and patience. Mark the desired curve on the material using a flexible ruler. Secure the material as you would for straight cuts. Use a smaller diamond blade for better control. Start cutting at the edge of the material. Follow the curve slowly and steadily. Make small, incremental cuts to stay on track. Avoid rushing, as this can lead to mistakes or blade damage.

Maintaining Diamond Blades

Maintaining diamond blades is crucial for their longevity and performance. Proper care ensures that the blades remain sharp and effective. This section will cover essential maintenance practices, including cleaning tips and storage guidelines.

Cleaning Tips

Regular cleaning of diamond blades prevents debris build-up. Follow these steps to keep your blades clean:

- After use: Rinse the blade with water to remove dust and debris.

- Use a brush: Gently scrub the blade with a soft brush to remove stuck particles.

- Dry the blade: Wipe the blade with a clean cloth to prevent rust.

- Check for residue: Inspect the blade for any remaining residue and clean it off.

Storage Guidelines

Proper storage of diamond blades extends their life. Follow these guidelines to store your blades safely:

- Store in a dry place: Keep blades in a dry, cool area to avoid moisture damage.

- Avoid stacking: Do not stack blades on top of each other. Use a blade holder or rack.

- Protect the edges: Ensure the edges are covered to prevent chipping or damage.

- Label the blades: Mark each blade with its type and size for easy identification.

Following these tips will help you maintain your diamond blades effectively, ensuring they stay in top condition for your cutting projects.

Common Mistakes To Avoid

Using diamond blades can be tricky. Many people make mistakes that can lead to accidents or damage the blade. Knowing these common mistakes can keep you safe and extend the life of your tools.

Overheating Issues

Overheating a diamond blade is a frequent mistake. It happens when the blade is used for too long without breaks. Overheating can damage the blade and make it less effective. To avoid this, allow the blade to cool down. Take short breaks during use. Water can also help keep the blade cool. If you use a dry-cutting blade, make sure to stop often to avoid overheating.

Incorrect Blade Selection

Choosing the wrong blade is another common error. Diamond blades come in many types. Each type is made for a specific material. Using the wrong blade can damage the material and the blade. Always check the blade’s label. Make sure it matches the material you are cutting. For example, use a masonry blade for bricks. Use a tile blade for ceramics. Selecting the right blade ensures a clean cut and a longer blade life.

Troubleshooting Problems

Using diamond blades safely involves understanding common problems. Knowing how to troubleshoot can save time and ensure safety. Below, we cover two frequent issues: blade warping and uneven cuts.

Blade Warping

Blade warping occurs when the blade bends out of shape. This can happen due to excessive heat or incorrect usage. Check the blade’s tension regularly. Ensure it is not too loose or too tight.

Cooling the blade while cutting can help. Use water or a cooling agent. Overheating weakens the blade and increases the risk of warping. Also, avoid forcing the blade through the material. Let it cut at its own pace.

Uneven Cuts

Uneven cuts can ruin your project. This issue often arises from an unstable cutting surface. Make sure the material is secure before you start cutting. Using a guide can also help to maintain a straight line.

Inspect the blade for wear and tear. A worn-out blade can cause uneven cuts. Replace it if you notice any damage. Additionally, ensure the blade is compatible with the material you are cutting. Using the wrong blade can lead to poor results.

Credit: diamondkingtools.com

When To Replace Your Blade

Knowing when to replace your diamond blade is crucial for safety and efficiency. A worn-out blade can lead to poor cuts and potential hazards. This guide will help you recognize the signs of wear and performance decline. Regular checks ensure your blade remains in top condition.

Signs Of Wear

Visible signs of wear are the first indicators that your blade needs replacement. Look for cracks or chips on the blade’s edge. These are clear signs the blade is damaged. Another sign is when the blade becomes noticeably thinner. A thin blade can break easily, posing a safety risk. Regularly inspect your blade for these signs to prevent accidents.

Performance Decline

Another key indicator is a decline in performance. If your blade cuts slower than usual, it may be time for a new one. Increased vibration during use is another sign. This often means the blade is out of balance. Difficulty in making straight cuts can also indicate a worn blade. Pay attention to these performance issues. They suggest your blade is no longer in optimal condition.

Frequently Asked Questions

What Are Diamond Blades Used For?

Diamond blades are used for cutting hard materials. These include concrete, stone, tile, and asphalt. They are essential in construction and masonry.

How Long Do Diamond Blades Last?

Diamond blade lifespan depends on usage and material. Typically, they last between 12-120 hours. Proper maintenance extends their life.

Can Diamond Blades Cut Metal?

Diamond blades can cut metal, but it’s not ideal. They are designed for hard materials like concrete and stone. Use metal-specific blades for better results.

How To Choose The Right Diamond Blade?

Choose a diamond blade based on material and cutting method. Consider blade type, diameter, and segment type. Match the blade to your specific project.

Conclusion

Using diamond blades safely is crucial for effective work. Follow the guidelines. Wear protective gear. Check the blade before each use. Never force the blade. Use the right blade for the material. Maintain your tools regularly. By doing so, you ensure safety and efficiency.

Always prioritize safety. Happy cutting!

Best Safety Diamond Blades

Bridge Saw Blades, Diamond Blades

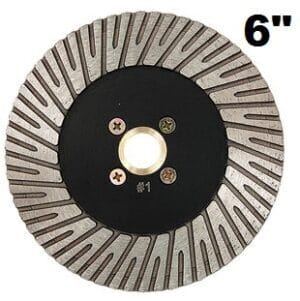

$249.95 – $299.95Price range: $249.95 through $299.95This product has multiple variants. The options may be chosen on the product pageTurbo Diamond Blades, Diamond Blades, Diamond Tooling

Rated 5.00 out of 5 based on 2 customer ratings(2)$16.90 – $95.90Price range: $16.90 through $95.90This product has multiple variants. The options may be chosen on the product pageVac-Brazed and ELP, Diamond Blades, Diamond Tooling

Rated 5.00 out of 5 based on 2 customer ratings(2)$32.90 – $42.90Price range: $32.90 through $42.90This product has multiple variants. The options may be chosen on the product pageConcave Blades, Diamond Blades, Diamond Tooling, Vac-Brazed and ELP

Rated 5.00 out of 5 based on 1 customer rating(1)$55.90 – $69.00Price range: $55.90 through $69.00This product has multiple variants. The options may be chosen on the product pageTurbo Diamond Blades, Diamond Blades, Diamond Tooling

$16.90 – $59.90Price range: $16.90 through $59.90This product has multiple variants. The options may be chosen on the product pageBridge Saw Blades, Diamond Blades

$249.90 – $378.90Price range: $249.90 through $378.90This product has multiple variants. The options may be chosen on the product pageDiamond Blades, Turbo Diamond Blades

$7.95 – $85.95Price range: $7.95 through $85.95This product has multiple variants. The options may be chosen on the product pageTurbo Diamond Blades, Cup Wheel Turbo, Diamond Blades

Add to cart$95.00Original price was: $95.00.$69.90Current price is: $69.90.Turbo Diamond Blades, Continuous Rim, Diamond Blades

$18.90 – $34.90Price range: $18.90 through $34.90This product has multiple variants. The options may be chosen on the product pageBridge Saw Blades, Diamond Blades

$219.90 – $259.90Price range: $219.90 through $259.90This product has multiple variants. The options may be chosen on the product pageMilling Wheels, Diamond Tooling

Add to cart$835.00Original price was: $835.00.$535.90Current price is: $535.90.Milling Wheels, Diamond Tooling

Add to cart$1,100.00Original price was: $1,100.00.$725.90Current price is: $725.90.Continuous Rim, Diamond Blades

$16.90 – $28.90Price range: $16.90 through $28.90This product has multiple variants. The options may be chosen on the product pageDiamond Blades, Bridge Saw Blades

$239.90 – $459.95Price range: $239.90 through $459.95Get notified This product has multiple variants. The options may be chosen on the product pageVac-Brazed and ELP, Diamond Blades

$34.95 – $39.95Price range: $34.95 through $39.95This product has multiple variants. The options may be chosen on the product page